The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail.

In sheet metal operations the volume of material reduced significantly.

Sheet metal forming is quite common for making shaped components from soda cans to automotive car bodies.

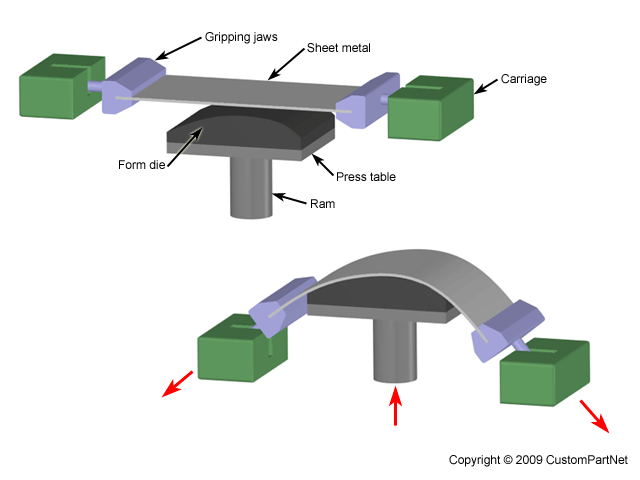

Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material.

Low volume to area ratio 14 5 the flow curve expresses the behavior of a metal in which of the following regions of the stress strain curve.

This distance is equal to the material thickness.

This doesn t reflect what really happens at the punch press.

A elastic region or b plastic region.

By default solid cad models of formed sheet metal parts usually have slightly more volume than the flat dimension.

Even though a formed part has more surface area which is why the solid model adds the volume to the part it actually has the same volume because of material.

For wire drawing to be successful maximum draw stress must be less than the yield strength of the exiting metal.

Popular sheet metal materials include.

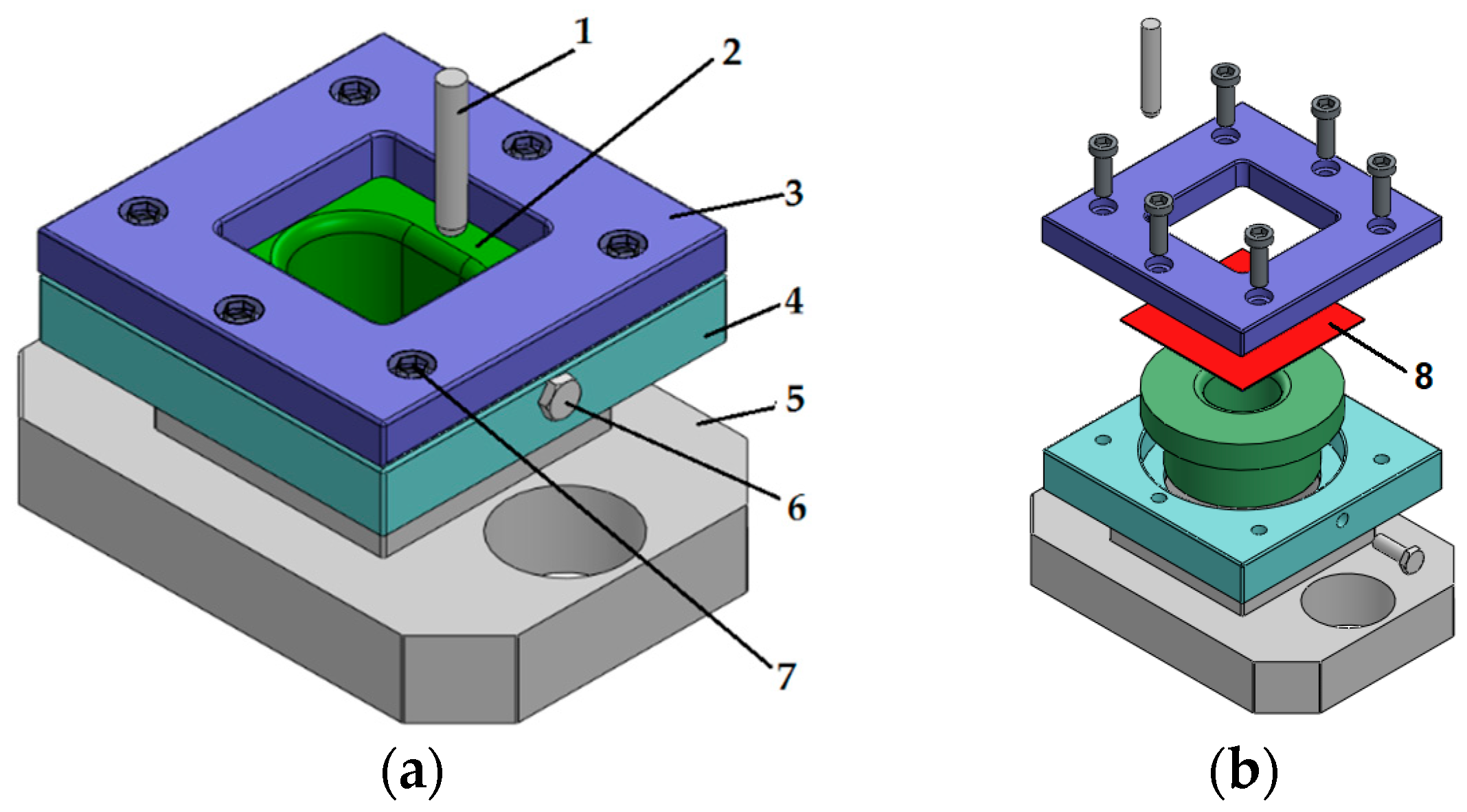

Forming and related operations performed on metal sheets strips and coils high surface area to volume ratio of starting metal which distinguishes these from bulk deformation often called pressworking because presses perform these operations parts are called stampings usual tooling.

Mishra in friction stir processing for enhanced low temperature formability 2014.

Thicknesses can vary significantly.

By doing so the sheet can be bent or stretched into a variety of complex shapes.

It is customary to refer to a material below the thickness of 6 35 mm as a sheet and thicker materials as plate.

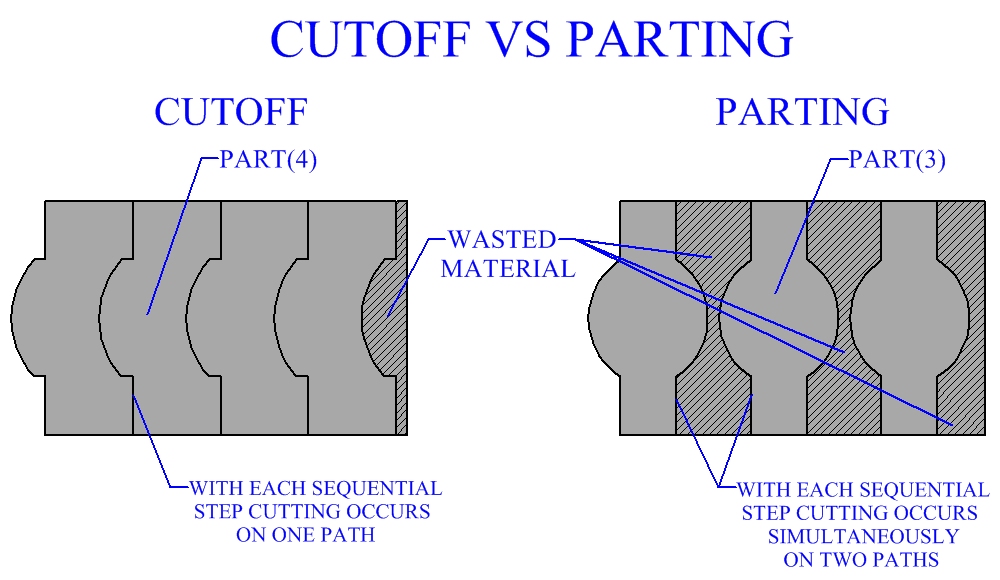

Most of the sheet metal cutting processes discussed can be performed on both sheet and plate metal although for many sheet metal operations difficulties will arise with increasing plate thickness.

A high volume to area ratio or b low volume to area ratio.

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal.

14 4 which of the following is typical of the starting work geometry in sheet metal processes.

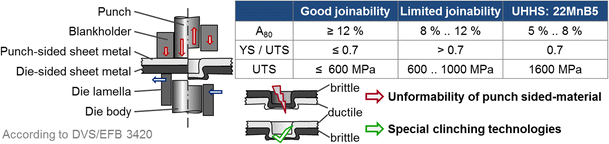

The choice of materials depends on the requirements of the application and factors in material selection include formability weldability corrosion resistance strength weight and cost.

Because this book is limited to bend forming which is the.

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered.

Sheet metal is metal formed by an industrial process into thin flat pieces.

Varied metals and metal alloys can be formed into sheets and used to fabricate sheet metal parts.

If the reduction is large enough draw stress will exceed the yield strength of the exiting metal.